-

Posts

1,870 -

Joined

-

Last visited

-

Days Won

191

Content Type

Profiles

Forums

Gallery

Everything posted by John/Horace

-

ABS, Traction Control light ON

John/Horace replied to Kavish Bhekharee's topic in Brake, Chassis & Suspension

How many miles on vehicle. The left rear abs sensor is the code. A new bearing assembly comes included with a new wire harness. Can change harness by itself, could be electrical plug or coil sensor on the end going bad. Not expensive part. If the internal abs pickup inside bearing is bad, new cable won’t help. https://www.rockauto.com/en/catalog/dodge,2014,journey,3.6l+v6,3300354,brake+&+wheel+hub,abs+wheel+speed+sensor,1912 -

There is no big brake bleeding problem. You just have a crappy dealership. Bleeding all four wheel drum brakes…like I did 40 yrs ago on 1960 VW beetles is hard. Newer cars are easier. Even gravity bleeding without even pulsing the abs system works if you know how to do it. Changing all the calipers must have introduced a new problem. Remanufactured calipers are sometimes faulty. Brass washer on flex line not seated properly can allow air in. Flex hoses can collapse internally. Etc. If you followed my instructions you would have found the caliper that is acting up. Which cross bleeding pattern you use …really doesn’t matter much.

-

Block test fine…means combustion gas test of glycol with a dye kit ? 2012 was the recall year for cylinder heads cracks, not a common issue.

-

ABS, Traction Control light ON

John/Horace replied to Kavish Bhekharee's topic in Brake, Chassis & Suspension

Check engine light often disables cruise with any kind of code stored. Resetting pin connections is a good starting point. If it’s intermittent…chance it comes back. -

Rough engine start for 20 seconds only

John/Horace replied to wowbones's topic in Engine & Transmission

Injectors can fail but are not that common. The most common cause of bad idling on the 2.4 engine is what Summer Solstice mentioned above. The electronic throttle body by 100k or so often starts to act up. Plastic internal gears wear out. Hitachi makes the oem unit, rockauto sells it. Usually sets codes and or a lightning bolt symbol. Some people use throttle cleaner and gently manipulate linkage with flap on it. Can temporarily help for a bit. But throttle assembly is a 2.4 wear item. -

I have used preprogrammed units made by Dorman and Schrader from Rockauto. Plug and play, they activated after about 10 miles of driving. Schrader is the manufacturer who makes Mopar oem sensors, I have read on other sites. https://www.rockauto.com/en/catalog/dodge,2014,journey,3.6l+v6,3300354,wheel,tire+pressure+monitoring+system+(tpms)+sensor,12036 Cloned preprogrammed sensors could be used if adding a second set of rims for a vehicle. Free advice worth everything you pay for it.

-

Welcome to site. Sounds frustrating. Which engine and how many miles. Pressure and leak down test on each cylinder useful.

-

Most likely a bad caliper (partly seized) and trapped air not gettting removed from system. The vacuum booster pump isn’t common failure. ABS unit is more common…but it’s fault lite on dash, not actual problems like soft pedal. Internal electrical issue. I would raise car on four jack stands. Remove tires and put few lug nuts back on to keep rotor square in case it has slight sideways movement. Have some one get in car and press brake pedal down as far as possible and hold in place (no pumping pedal). Then use a pry bar across each of the rotor studs (where nuts are to avoid thread damage) and see if you are able to turn rotors. All should be locked without allowing movement. Any wheel that isn’t has an issue. Brake bleeder screw loose slightly then put on 2-3” length of clear hose, open bleeder a little more to allow for fluid to flow and watch hose for air bubbles. Light tapping on caliper allows air to go to top of casting. Do a second time to make sure no more air. Catch fluid with a rag, avoid getting on painted surfaces. If you can’t clear the air, that caliper is partly seized and needs rebuilding or replacing. Rear calipers have parking brake built in, they can have return arm not fully retracting by the visible spring. Pads on that side will have accelerated wear. Remanufactured or new caliper fixes it. Cycling parking brake during bleeder process is needed to properly clear air. At least in my experience. Always cross bleed, start with passenger rear first, the longest line, then driver front.

-

ABS, Traction Control light ON

John/Horace replied to Kavish Bhekharee's topic in Brake, Chassis & Suspension

Google says code c0037 is not vacuum pump but abs wheel speed sensor. That code indicates a problem with the rear left speed signal. It may suggest that the sensor has failed, which is likely, but it could also mean that the tone ring is obstructed by debris or that the wiring is damaged. You can buy the wire harness with built in coil for $40 ish and not change bearing. But internal sensor ring in bearing might be problem. Bearing is a wear item, often get noisy by 100-150k miles anyway. New bearing assembly usually comes with the new abs wire harness. -

Always a film of dish soap or even synthetic grease on rubber part and the opening it goes in. Heating with a hair dryer can also soften up rubber and make more pliable. Haven’t done cam seals but I haves used large socket to pop in lip seals. Need largest socket possible, close to seal diameter as possible. Reduces flex which affects diameter a bit. Need to keep seal as square as possible, don’t want to press in on an angle.

-

ABS, Traction Control light ON

John/Horace replied to Kavish Bhekharee's topic in Brake, Chassis & Suspension

Welcome to the site. The most common cause of these codes is a bad abs sensor on one of the four wheels, but it also normally has a specific abs code. Not all cheap code readers will pick up abs codes. There can be lots of issues on 10 yr old vehicles in the rust belt areas. Anything from a weak older battery (5yrs plus) to rodents chewing on wire harness or main electrical grounds not making good continuity (all grounds on front strut towers need to be cleaned and left with fine film of dielectric grease, bare metal exposed and also light film. Some people add higher gauge ground wires for a long term permanent fix. Search on site has info on how, Dean H has great posts about this. A good two way scan tool is best way to fix mystery electrical issues. After grounds, battery etc have been eliminated first. -

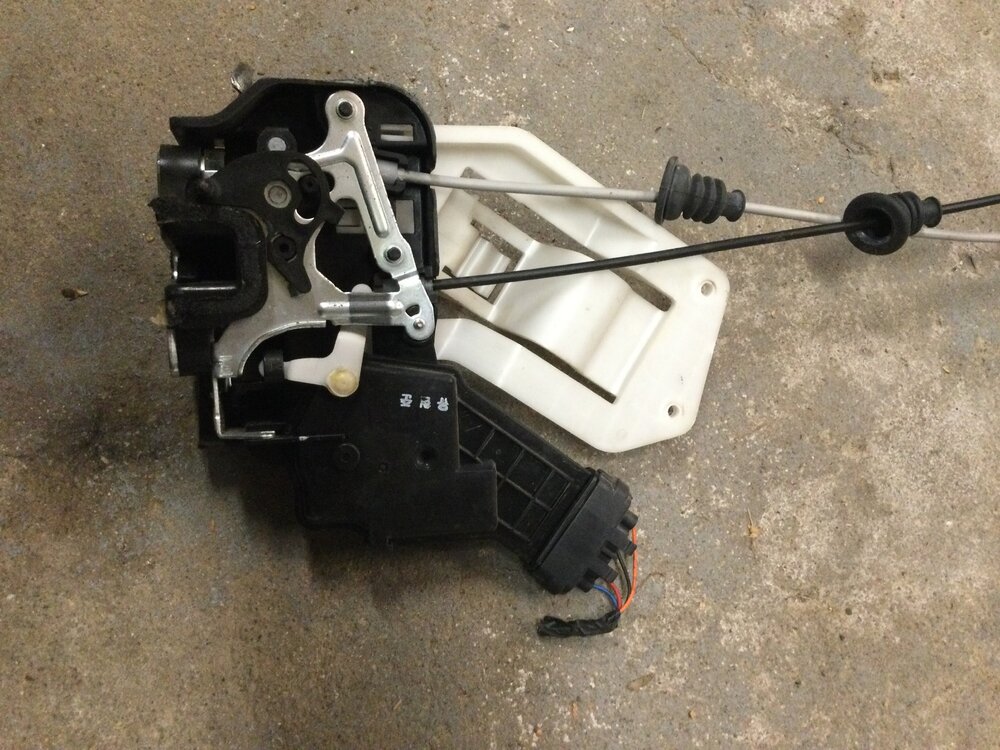

Door lock actuator "clunks" but does not actually lock the door

John/Horace replied to trevcda's topic in Interior

Try lubing up the door latch mechanism. Cycling lock with door open, lock and then lift handle to unlock. There are springs and a few other pivot joints that can stick or not cycle in sequence. Solenoid moving isn’t the only thing occurring when door actually locks. Even cables like mentioned are part of assembly. Here is a pic of a door latch assembly off my daughters Kia rondo. A little finicky to change. -

I'm back with another issue!

John/Horace replied to Shawn855's topic in Electrical, Battery & Charging

I think this unit was rated at around 60 milli amp continuous draw. It was on car when she got it and appeared 8-9 yrs old. May have had an internal issue because it was over drawing power. But body was slightly better than usual for rust belt vehicles. Brake lines were rotted and I replaced with nickel copper lines. With a multi meter you can actually see the electrical energy pulse on the frame. But with so much plastic and isolated components from main subframe there are still parts not being protected. AGM battery’s would really suit this type of application…and even your killer sound system power requirements. Faster charge and slower sitting discharge etc. Anti rust sprays annually are still the best protection in rust belt areas imo. Most of them are not actual petroleum oil but environmentally friendly ingredients. Like lanolin, wool oil, refined mineral oils (like medicinal or baby oil) etc. Swelling rubber can be risk from some of the sprays. -

I'm back with another issue!

John/Horace replied to Shawn855's topic in Electrical, Battery & Charging

Here is a electronic module I took off my daughters 2010 Rondo …for the same reason. Car couldn’t sit two weeks without battery being low. Maybe with an AGM battery they might be a better option. Have been around for years, sacrificial anode technology used on submarines etc. Keeps a low voltage pulse on entire metal body of car. I lthink it was adding a 110 milli amp to parasitic load, added up to quarter amp total draw. Too much. Car still had rust, although less than a normal non undercoated vehicle. Not worth the grief IMO. -

Vibration on the steering wheel and chassis

John/Horace replied to Kiril's topic in Brake, Chassis & Suspension

Great news. I just figured your a persistent stubborn guy who wanted his car fixed right. Mechanical repairs often require that. Some high speed stuff will gradually work its way down to lower speed issues down the road. So dealing with it early stages is not the wrong approach. And I still have two brothers…the ties that bind. -

The scanner you have can't retrieve most transmission codes. Even if dash mil light is not on, sticking in first gear would generate codes. Stop by a transmission shop and ask them to trouble shoot the problem. Plug in a bi-directional scanner that can be used to cycle all the sensors to find problem. Buying random parts not a good idea. If your lucky it's a bad sensor (input or output speed sensor maybe) and not entire transmission that needs rebuilding.

-

And water should not be trapped there. So you got the right spot. Trapped water could accelerate rusting out of car long term. Leaks are one of the most annoying car problems you can have; not often easy fixes. I propped up carpet with a few pieces of 2x2 wood. Then ran a hair dryer on low for an hour ish. If you get a mold smell, a few laundry softener dryer sheets help a bit. Carbon activated dash hvac filter also useful.

-

A body shop would remove your driver fender and use a product called seam sealer. Its a polyurethane used when cars are built at the factory. But if the factory drain holes are plugged, still might leak. I just feel the extra holes are a simpler cheaper solution. The fuel lines, brake lines and wire harness have to be avoided, obviously. Have had no leaks in a year now. In a previous life I use to be a bs&f assembler ( bench and structural airframe assembler) for an aircraft company. Use to drill hundreds of holes a day building wings, nasell, floor sections etc. DC9, DC10 and KC10 Air Force tankers. So I have a bit of practice drilling. Nice new sharp hss drill bits needed, small pilot hole first, then open up to bigger sizes. The three added holes are right behind the passenger front wheel, at the start of the channel that runs under the doors. Drains the water before it gets into the foam and leaks around the various anchored clips.

-

how to strengthen rear shocks for towing 3000 lbs

John/Horace replied to Pbright220's topic in Brake, Chassis & Suspension

That weight wthout trailer brakes, illegal in some jurisdictions. The journey transmissions are not that tough...extra transmission oil cooler would be very good idea. Heavily reduced fluid change interval, the ATF4 is only semi synthetic. -

My leak was passenger side, but new hole location should be similar, you can see wiring harness under carpet, I stayed away to avoid accidents. I used an extra long drill bit to clear out the factory holes. Two of them had crap in them. Probably flakes or rust, I'm in the rust belt here. This car was undercoated multiple times, the main body above is actually quite good still. The car is designed to be self draining from windshield cowling flow. Water is suppose to flow to drain holes that can handle the volume. When you drill through you hit an empty channel. Not into the carpet and car interior...like some people are thinking.

-

Vibration on the steering wheel and chassis

John/Horace replied to Kiril's topic in Brake, Chassis & Suspension

A dynamometer allows running car at speed with the wheels supported. Four wheel supported model for awd. But usually no proper access underneath. That why vibration analysis sensors normally used. A regular hoist with wheels hanging not that great. Can’t run up to 80 mph for sure. Wheels unloaded would affect normal noise creation as well. -

Sounds like progress…good. This can be a very frustrating problem. There are quite a few holes in the door sill that trapped water can move to unfortunately. Silicone won’t stick to itself, that’s why I used polyurethane. I don’t think water is ever suppose to make its way inside the door channel. The foam is for sound deadening only. It may be the extra drain holes I added were the real solution. They all piss water underneath car now when the hose runs on the windshield. Inside stays completely dry.

-

Welcome to forum. There are some claims that non OEM filters can cause that code. If your sure pressure fine at low and high rpms, start with new oil filter and give it a few driven cycles. Don't start looking at oil pumps and solenoids until simple stuff tried, low milage engine. TPMS can be finicky, the batteries get weak eventually. Need a good scanner to really know what's happening. The schrader and dorman preprogrammed sensors from Rocka have both been plug and play for me. Not all tire shops have a good scanner and are interested in dealing with the light. Try another shop.