-

Posts

1,590 -

Joined

-

Last visited

-

Days Won

142

Content Type

Profiles

Forums

Gallery

Posts posted by John/Horace

-

-

Lots of power options on newer cars now. Alt work harder imo. Mine went at 90k miles or 145k kilometres with the burning electrical smell and voltage fluctuations. Low battery warning on cluster came on, ecm disabled radio and various other accessories so electric cooling fan would be the last thing to lose power.

Drive pulley torque decoupler has bearings inside; can be cause of some early failures. Fuel economy feature I believe.

After 2015 ish there was a plastic top guard that mounted on top of alternator. Even oem remanufactured unit from dealer ( with a two year warranty) comes with the plastic guard and hardware. It prevents oil from dripping on hot alt and causing a fire hazard. Valve cover could easily leak in this manner. I was happy to get this upgrade item with the dealer reman unit; at a lower price than other aftermarket reman units. In stock with a refundable core charge.

A few alt failures but almost no starter motors documented on this site. Starter looks like a bear to get at, so be happy it was alt.

New trumps reman always; but price difference can be huge.

-

From the google…

P000A is stored when the actual position of the camshaft differs from the position that the PCM expects during camshaft phase changes. The “A” in code P000A refers to the intake camshaft. The “B,” on the other hand, refers to the exhaust camshaft

Dirty or low oil can trigger cam shaft codes.

Lightning bolt symbol like luzia is saying is usually expensive electronic throttle body. Mechanics have a hand held obd analyzer that can cycle sensors to isolate if it’s a sensor, wire harness etc. Avoids top 10 guess method.

-

Welcome to the site. Push button start very sensitive to getting full 12 volts to function. Battery warmer pad rather than block heater would probably help.

Need a very strong battery at your temps, if it’s more than 3 yrs old or alternator weak you will have problems. Cranking amps on battery and voltage output from alt need checking. BMS systems on newer cars might get in way where you are; sees low voltage from cold and interprets as draw from item left on. Shuts system down. Sensor right at negative terminal of battery I think sends signal to pcm.

Key fob has driver door lock key built in. Little tab releases key. May have to lube with deicer etc first time used. If fob battery dead or low, press end of fob against start button directly. Use it to cycle button, signal gets picked up.

Portable lithium booster packs , biggest you can find , helpful this time of year. -

Find out who gets the revenue from all those flash and banner ads. Tell them to hop to it. Or pay for moderator bots. ?

-

People get stuck and get carried away, burn up the silicon/oil. Clutch plates get damaged and seals start leaking.

Subaru forums say it’s usually 1,000,000 (cst) PolyDimethylSiloxane fluid in most vc diffs. Not much fluid 50-80 ml maybe, measure accurately what comes out if possible. Could be half black paste and not meaureable. Getting Mopar fluid would help odds of successful fix. Pic is of a Subaru vc .

Fluid should last life of vehicle I think; if not abused. My 3 vc vehicles have never needed it changed. Although Jeep np249 transfer case was causing hopping at 200k miles. Needed it.

-

No not at all. Very simple awd system that will allow one wheel on each axle to get you a little farther in bad conditions than just front wheel drive(single wheel). Can’t even force on back wheels with over ride switch, so no off roading should ever be attempted. Ground clearance also not enough for off road driving. You can probably get stuck on wet grass with this vehicle if you have bad luck and minimal driving skills.

It’s a system designed to allow you to keep control in minor snow ice or mud ; on existing normally maintained roads. Your AI algorithm has good platitude setting; need to tweak tec comprehension…badly. JohanBot. -

ESL speak with no grammar or punctuation, or just bad AI coding. Can’t tell.

15 hours ago, johanbrandon said:did you people really owned that much vehicles time to time. if did wow car enthusiast

-

What are the Possible Causes of the DTC P2173 Dodge.

Large Vacuum LeakFaulty Manifold Absolute Pressure (MAP) Sensor

Manifold Absolute Pressure Sensor harness is open or shorted

Manifold Absolute Pressure Sensor circuit poor electrical connection Faulty Throttle Position (TP) Sensor ⚠ D

Some map sensor failures have been documented on site, $30 part. Need to diagnose problem. -

Good oil pressure, so driving a few days shouldn’t matter with intermittent noise IMO. It wouldn’t be changing a few rockers arms on the front cams. At $10 ish each mechanic will likely change them all.

But if you also change front cam (s) then timing chain, hydraulic tensioner, all front covers etc all coming off. Can’t reset timing other wise. Chain tensioner shouldn’t be reused but replaced, $200 ish part etc. So lots of work.

Just changing rockers isn’t a half assed repair. If there is minimal wear and you can leave cams in place you wallet shouldn’t bleed much and engine might last as long as you need. I agree with poster tsteve5 on this approach.

The well know hemi tick on the V8 5.7 engine is similar problem. Wear issue maybe caused by MDS cylinder deactivation set up ( forced fuel economy tec) or oil flow to top end. No one really knows why, but changing rockers and cams often needed. Ram forum has thousands of posts talking about it. Only affects some vehicles; not always linked to lack of maintenance.

Good luck with repair, bad time after Xmas for big expenses.

-

Bottom end issues I think has more of a knock to it, hollow sound. Great advice on cheap mechanics stethoscope. Had one for years.

The serpentine belt can be removed and engine run for 20-30 seconds. Eliminates most noises but may generate a few engine codes. No water pump running so don’t push time factor. If necessary wait a while and do a second quicki test.

Like OP is saying. Need to address right away to avoid cam damage if that’s the issue. Removing cams means chain and tensioner and front of engine all apart. Huge labor costs, engine swap usually cheaper. Make sure oil pressure on cluster is in proper range when noise is present on hot engine. How many miles on engine?

-

-

The last post has to be some kind of AI robot crap. It completely ignores the mention of $2k + expensive rattling top end engine problem. There is no testament to good maint and reliability bla bla bla. I’m sure owner is not happy at all at only 100k mikes for this type of expense.

To actually answer his question, which johanbrandon clearly didn’t. There are a few docuemented cases of this with the 3.6 engine, on this site, but it is not a commmon issue at all, especially at your low milage. I would try switching to a Mopar filter and new top grade oil immediately, see if sound changes. Maybe even high milage 5W30 oil considering your location. They don’t usually just start loud ticking. Top end wear slowly increases and sound level follows.

-

Airbag clips, always a little crazy. Kinda on topic IMO.

-

Highly unlikely they will be plug and play. If part numbers were the same, you could chance it. But with airbags and other critical stuff tied in to wire harness, maybe not a good idea to play with that. In most countries the insurance companies would void your policy coverage so fast…your head would be spinning. In an accident situation.

-

The fuse box configuration determines which fuses are on keyed or continuous power. So the wires leaving a keyed power outlet fuse would have to be rerouted to a spare fuse slot that has continuous power set up. And vice versa.

It’s doable but would need to be done properly with solder and heat shrink and proper gauge wire. It’s temping to just pig tail off the nearest existing wires. But you don’t want to overload circuits with unknown power loading.

Usually not enough wire to just remove one connection from back of fuse and feed into another fuse. Automotive wire harness has very little built in slack imo.

-

Haven’t worked on the Chrysler 3.5 timing belt. But I have changed close to a dozen belts on various vehicles from Honda to Hyundai V6’s. Did a 2.7 Rondo V6 last year for my daughter. Belt, idlers, tensioner, CPS sensor and water pump. You only want to go in there once if possible. A lot of labor removing crank pulley and plastic covers.

If it’s out one tooth generally a vehicle will be hard to start but it will run. Timing out around 6 degrees so awful idle and not really driveable. Two teeth and engine generally won’t start. In neither case is there any contact with valves or engine damage. It’s very easy for even an experienced mechanic to have timing out one tooth on any of the timing gears.

There is a small flexible cam that mechanics can use to inspect valves through plug hole for damage. Time consuming job some guys won’t want to do. If car just died without a bang or lurch. Maybe the valves are still ok and it’s worth trying to get an inspection. The real proof is pulling all covers and seeing if timing marks line up. A lot of labor involved. Experience needed to assess if marks are properly aligned.

I’m pretty sure your code is from timing being off from belt jumping. Belt may look ok from quick inspection, its the small teeth underneath that matter, there is probably one section of a few damaged rubber teeth or slots. Look at very bottom of plastic cover by the crank pulley for any small chunks of rubber.

-

How did you clear code, with a reader. Pull battery power for 5 mins, code may clear.

-

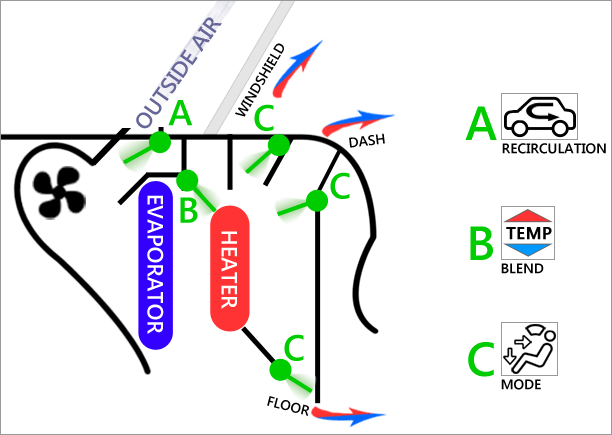

It allows in outside air. When car is turned off it will try to cycle to open position, vent interior moisture. When it’s open you can see outside light coming in threw dash filter. Removing filter helps seeing if it’s stuck closed. People often poke it open to temporarily fix problem. Changing it is an awkward job even with glove box door dropped down.

-

With 3/4” drive you can get a a few foot long pipe and add it to the breaker bar. Remove nut with hub cap off and wheel on the ground if possible. Safer and weight of car helps. Counter clock wise to loosen.

Even heat from a torch helps with seized threads. Impact gun which vibrate when used is always best, but not essential.

Its only torqued at 100 ft pounds; removing rust on exposed threads with wire brush will prevent damage on nut threads. People resuse the old nuts but technically they are suppose to be replaced on most vehicles after removal. Dealers do.

-

Link would be helpful. Rear arm oem is pricy. Cheers.

-

Thanks for follow up. Curious how many kms on the original viscous coupler now ? Had to change both side lip seals on our 2014 rear diff. They literally rotted out from road salt and started leaking. Time consuming crappy diy job. Never went low enough to cause any damage. At 244k kms or 151k miles now.

Now that I have learned of vent issues, plan on getting to it and cleaning it out. There has been a handful of people on site that had similar oil leaks with coupler. Have owned multiple jeeps and trucks with awd, haven’t experienced this problem yet. But the Journey sees lots of mud and salt…and I’m never lucky. -

These guys list two versions, check actual Mopar number on the sensor. Their Pics are usually accurate.

I don’t work for these guys.

-

I’m not a big tv person. Friends sometimes send me stuff. Yeah Merry Xmas and haaapppy new year.

-

The comments are the best part. They range from “needs 350 D cells not included ….to please crash test…immediately.

https://jalopnik.com/russia-has-new-ev-thats-totally-going-to-destroy-tesla-1851117732w

Journey 2012 won’t start, no remote entry, nothing working inside

in Alarms, Keyless Entry, Key Fobs, Locks & Remote Start

Posted

Did battery actually get to full charge. Most chargers will show battery level, some even show %.

Should be around 12.5-13 volts if full. At -45 C a lead acid battery at full charge still only has half its cranking amps.

Check connections on new battery. Should not be able to twist top terminals with a gloved hand.

A boost from a running car or truck slightly reving will add a lot of cranking amps.