khnitz

Journey Member-

Posts

21 -

Joined

-

Last visited

-

Days Won

4

khnitz last won the day on March 22

khnitz had the most liked content!

About khnitz

Profile Information

-

Region

U.S. Great Lakes

-

Journey's Year

2014

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

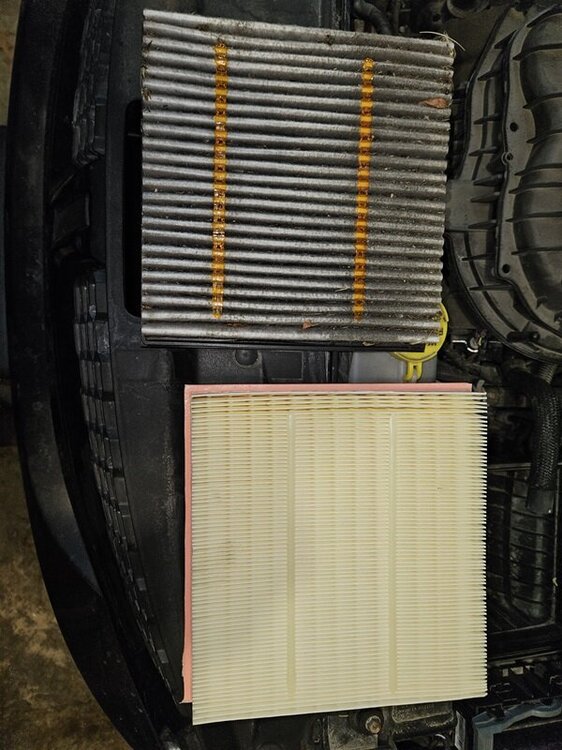

Some other details I made note of, but forgot to add to the summary post... The old spark plugs looked to be original, Champion RER8ZWYCB4. The new plugs I used were NGK Iridium LKR7DIX-11S . The air filter I removed (maybe it was original?) had 23 pleats and the extra debris (charcoal?) filter membrane. The new air filter was an AC Delco A3618C with 78 pleats. The oil filter that was removed was a Napa 2100010 with 48 pleats. The new Mahle OX1213D has 57 pleats.

-

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

-

Here is a picture of the trim clip I used on the that passenger seat trim. Disregard the small hole above it - my aim was off when I drilled the first pilot hole. The trim clip is lined up with a hole in the seat frame behind it that is for a clip on the back side of the panel that cracked off (I think it was for a clip, as it's not there anymore because it was broken off). The hole size was close enough with a 5/16" drill bit to match the hole in the seat frame and fit the panel clip. The clip I used is one where the base is pushed in, and then the center pin is pushed into it to lock it in place (like a hollow wall anchor). It is solidly in place, now. There is a clip on the driver's side seat trim that is broken off, too, but I don't think the panel clip solution will work over there because of the power seat switches. When it comes time to fix that, I think I'll use a rivet nut in the hole in the seat frame, and then a bolt with a low profile screw head but either and integrated washer or wide flange to secure it. And, I'll also put a spacer over the bolt on the back side of the trim to hold it in the proper standoff position.

-

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

-

Indeed 😁 I finally got to put one in about 2.5yrs ago and it has made a world of difference. To be able to work on brakes while standing up is sooo nice. The installation saga for mine is documented here .

-

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

-

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

-

larryl reacted to a post in a topic:

What Did You do to your Journey Today

larryl reacted to a post in a topic:

What Did You do to your Journey Today

-

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

-

2late4u reacted to a post in a topic:

What Did You do to your Journey Today

2late4u reacted to a post in a topic:

What Did You do to your Journey Today

-

I completed the maintenance work over the last couple of days and the 300+ mile drive back to IL went without a hitch. I average 23.3 mpg at, let's just say *quick* speeds, (according to the Fuel Economy reading on the IC) on the last 200 miles - I reset it after my last fill-up. That was about 2mpg better than I saw on the drive from IL to MI before all the work. Granted, that's a small sample size for comparison. Here are some pictures of what was done... Old vs. New air filter. I couldn't read the make of the old (original??) air filter, but the new one is an AC Delco. I like the additional pleats vs the old one. In looking at how-to videos on removing the upper intake manifold to access the spark plugs, the ones I found talk about completely removing the rear intake bellow (somewhat under the cowl, between the throttle body and the upper intake manifold) first, and having to remove coolant hoses, etc. to make room to slide it out. I actually found it easier to move that bellows off of the TB and move it just a little back to access that last upper intake manifold bolt that is hidden by it, and then remove the upper intake manifold first. Then that bellow comes out easily and completes access spark plugs on the rear cylinder bank. The spark plugs were the OE Champion, and I used NGK Iridiums as replacements. Here are the old plugs, and a comparison of an old and new plug. I also rotated the tires and bled the brakes. While bleeding the brakes, I noticed the rear brake pads were getting low, so I went ahead and changed them. While I had the upper intake manifold off, I took a picture down of the back of the intake valves. They look pretty good/clean. Again, my in-laws' Journey had ~57k miles on it at this point. I also removed the platform running boards they had on there (they are hurting, more than helping, access at this point of their mobility). Let's see, what else...I topped off the coolant and power steering fluids. Oh, and I replaced the serpentine belt, its tensioner and idler pulley, as well - with the car being 10yrs old and the belt being original, it was just a preventive measure at this mileage. Another item - the lower seat side trim piece on the passenger side had been broken loose from repeated entry/exit to the seat. I found a way to use a hole on the seat frame and a trim panel clip to drill a 5/16" hole and secure that trim piece. Aside from having to live with the appearance of the trim clip, it holds that plastic piece securely and works for us. I'll get a picture of that later today and post it.

-

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

khnitz reacted to a post in a topic:

What Did You do to your Journey Today

-

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

5rebel9 reacted to a post in a topic:

What Did You do to your Journey Today

-

khnitz started following What Did You do to your Journey Today

-

I'm performing some maintenance on my in-laws' 2014 Journey this week. The last bit of service I did on it was in 2022 (replaced LF wheel bearing/hub) while on the road at their home in IL, but this time I brought it back to my house in MI to tackle the work. On the to-do list: Oil & Filter Change Bleed/flush Brakes Rotate Tires New Serpentine Belt, Tensioner and Idler Pulley New Spark Plugs New Air Filter Remove the "wings" (large-platform running boards) Install a Panavise mount for a phone holder There's just under 57k miles on it now, so this should give it a nice refresh.

-

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

Thank-you. I try to help them where I can At least this wasn't as bad a repair as the 2 engine replacements I did on my son's Chevy Equinox

- 35 replies

-

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

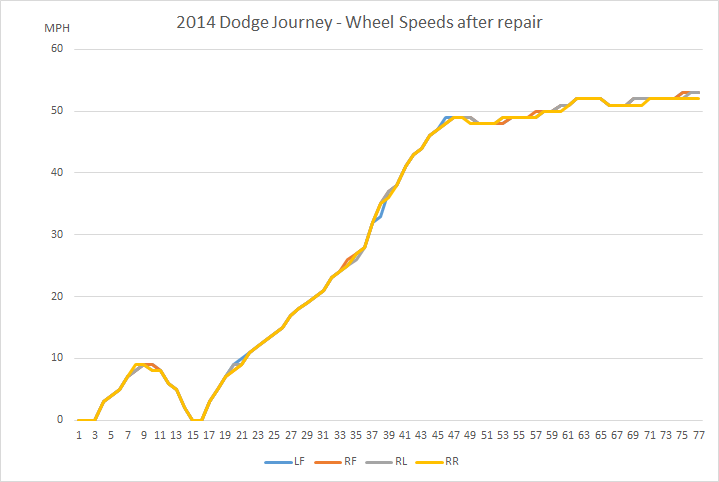

So, just a few more images to close this out... Here is the picture of the old vs. new wheel hub, but trying to explain what was broken. The picture shows the back of the wheel hub/bearing. The "reluctance ring" used for the wheel speed timing was decayed and broken off in pieces (the remaining pieces are shown in the inset image, but I had cleared away those parts in the larger image of the old hub on the left). I'm trying to highlight that in the picture below. The green arrow is pointing to the timing ring on the new wheel hub. It looks like the seal for the wheel bearing, but it's actually the reluctance ring and it is not a seperately available part - it is press fit to the back of the wheel hub bearing. And here is a chart of how the four wheel speeds tracked over a test drive I made. They all tracked essentially together, with slight differences related to the timing of the measurements by the diagnostic tool as I was changing vehicle speed, or while going through curves in the road. Thank-you for all the help offered here in the forum as I worked this repair to completion for my in-laws. Hopefully this thread will help a next person trying to diagnose and accomplish a similar repair!

- 35 replies

-

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

2late4u reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

John/Horace reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

John/Horace reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

I'll post a more detailed wrap-up/summary when I get back home tomorrow. But, as a quick update: this is FIXED! That is the timing / reluctance / tone ring at the back of the front wheel hub, and everything is working correctly. I put about 10 miles on it this morning: all warning lights are off and all the wheels are reporting correct speeds. So, we all know the wheel speed sensor installs into the spindle on the fronts, but it is clearly understood now that the tone ring is part of the wheel hub assembly as a reluctance ring at the back of the bearing. It is integral to the wheel hub/bearing, and is not a separate part. It is also NOT part of the CV axle, so you DO NOT need to replace the CV axle to fix a wheel speed issue on our Journeys. Somehow, this info should be part of the part descriptions at RA, AZ, and elsewhere, but it's not...yet.

- 35 replies

-

5rebel9 reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

5rebel9 reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

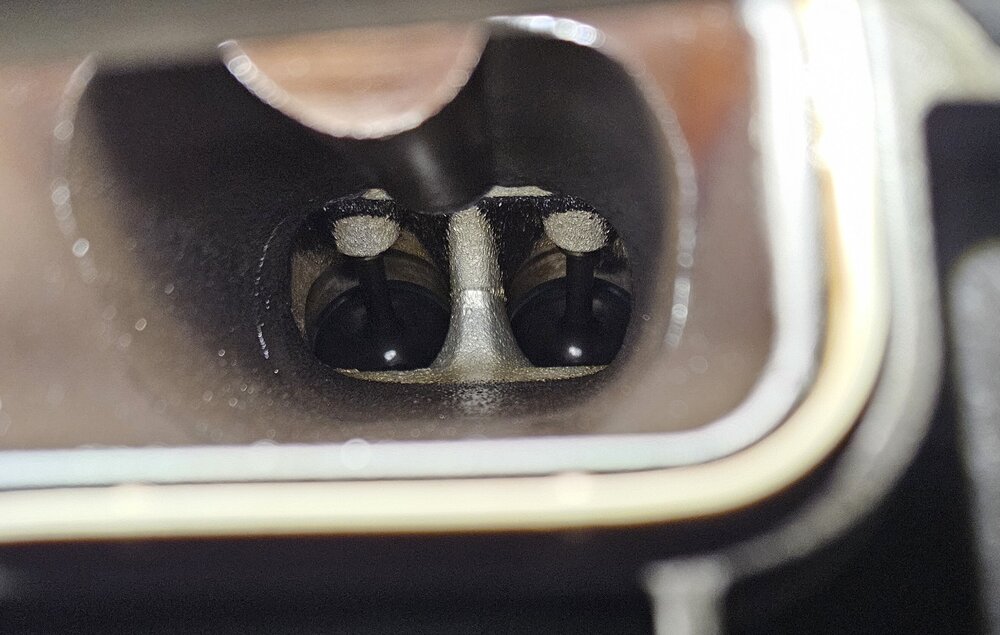

Everything is back together. Turning the hub by hand and having my son watch the wheel speed readings on the diag tool, it seems to be tracking fine and not jumping around. We had my in-laws driveway sealcoated while I was finishing up the repair, so I'll get a test drive done in the morning and will post up the final results then. Here is a picture of the old and new wheel hub: And this is an image of the new wheel hub installed. The sensor tracks nice and close to the black timing/reluctance ring: And another shot of the reluctance/timing ABS "tone ring" and sensor: I noticed the little bit of rust flakes there, and took a q-tip and some rubbing alchohol to clean out the rest of the flakes before reassembling everything.

- 35 replies

-

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

The tech at AZ indicated that the dark ring (pointed to with my small screwdriver in the photo below) is magnetized and provides the timing for the sensor. Based on the sensor position in the hub, it makes sense. And, that ring was decayed on the original hub. Now on to the hardware store to get a big-ass-chisel to seperate the hub from the spindle. The rotor hasn't broken loose yet, either (rustbelt repairs are such fun ?).

- 35 replies

-

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

khnitz reacted to a post in a topic:

Replaced LF Wheel Speed sensor, now traction control light but no codes

-

Well, we're back in IL soo er than expected, but I ha e the replacement axle to install. The original one came out easily enough. So, I'm more confused. There really doesn't seem to be a tone ring anywhere that is a part of the CV axle. At the back of the wheel hub/bearing, there were signs of a rubber dust shield or something that spins with the hub - that seems to be the only thing close enough to the wheel speed sensor to have provided a means to count. It was all rusted and falling apart. The CV axle meets the hub/bearing too far back from the sensor to be the source of the count. I'll be going to Autozone in a bit to inspect a new wheel hub in person. As found: Old vs new CV axle: After clearing out the extra "seal" and rust:

- 35 replies

-

Oof - at least it is being covered under warranty for you! Are there any other steps they can take to prevent the same issue from happening with the new module?

- 35 replies

-

I continue to dig around for information on the exact location/structure of the tone wheel, and something I came across was a recall notice 15V-675. The recall work was to add extra sealing to prevent water ingress to the ABS unit that could result in a failure. A catastrophic failure from that water ingress would result in a C2200 fault code, and it definitely doesn't have that. Also, I checked their VIN and the recall work was performed in 2015. So, after confirming with their VIN, the Mopar PN for their FL CV axle is 68079565AB. I'll be going with a Duralast 14293N as the replacement. But, again, it will be a little bit before I am in IL again and can replace it. While the axle is out, I'll make sure to clear any debris out of the inside of the hub where the wheel speed sensor pokes through, too.

- 35 replies

-

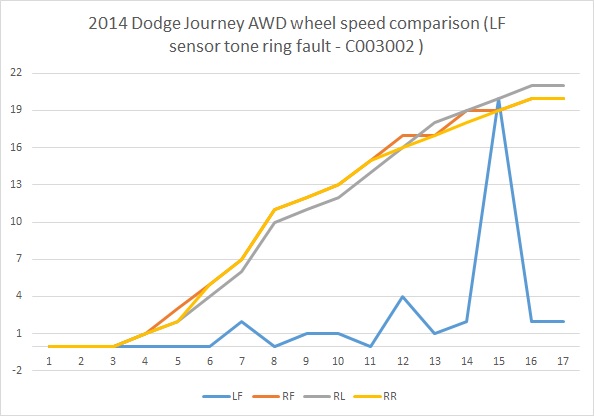

I'm trying to find PC SW that will let me export data from my Foxwell NT510, but no luck so far. In the meantime, I manually plotted one of the data recordings I made. Yesterday, I was able to get the speed of the Journey up over 5mph by coasting downhill in neutral - I wanted to see how the wheel speeds tracked at greater than the 5mph that the TCS was limiting the vehicle to when in drive. BTW, once the speed when coasting had exceeded 20mph and I went back into drive the vehicle drove normally (but with the warnings lit). Anyway, here's what the data looked like (my guess is that the log is at once-per-second or so. So, I would say that somehow part of the LF tone wheel has deteriorated so that the wheel speed sensor is only able to partially count wheel speed during a rotation of the wheel. The other 3 sensors are tracking together. BTW, in previous replies, it was suggested to examine the vehicle wiring, as well. The harness looks clean and un-chewed, with no obvious spots of wear or corrosion, either. I would not say that the graphed results completely rule out a wiring issue also being a cause, but given that there were no sporadic readings when the rest of the sensors were measuring 0mph and that there are no codes for the sensor itself (just the code for the tone wheel due to the readings), I'm not inclined to think it's a wiring issue.

- 35 replies

-

Thanks for checking on that at O'Reilly's! I had to think a moment on the "5 ribs" advice, but then I got it. Yeah, I'll keep an eye out for that. And I'll do a little more research on the tone ring before pulling the trigger on the replacement axle. Definitely doesn't seem like it's part of the bearing/hub on the fronts, and looking through the sensor hole at the CV joint end while rotating the hub only showed a smooth surface...no timing "sprocket" teeth (like a gear) or holes (like a film reel). I will post further updates, though it may be while as we don't have a trip planned back to IL for a couple of months.

- 35 replies